29 Sep 2021

Sustainable packaging: let's sort it out!

In total, France produces five million tonnes of household packaging per year (source: ADEME). While 70% of household packaging is currently recyclable, this depends above all on the materials used: 100% of steel, 85% of glass, and 64% of paper/cardboard packaging are recycled, but in the case of plastic, only 28% of packaging is recycled (source: CITEO).

To move in the direction of sustainable development, to meet the expectations of consumers who are increasingly concerned about the environment, and to be in line with regulatory changes, professionals in the agrifood and the packaging sectors have developed various packaging solutions which are more sustainable. Biodegradable, bio-based, bioplastic... There are many alternatives. But what exactly is it about? How do we sort these concepts out? Below is an overview of sustainable packaging solutions, following our webinar organized on the subject last May (see video here – in French).

Petroleum-based, bio-based, biodegradable… They don’t all go in the same bin!

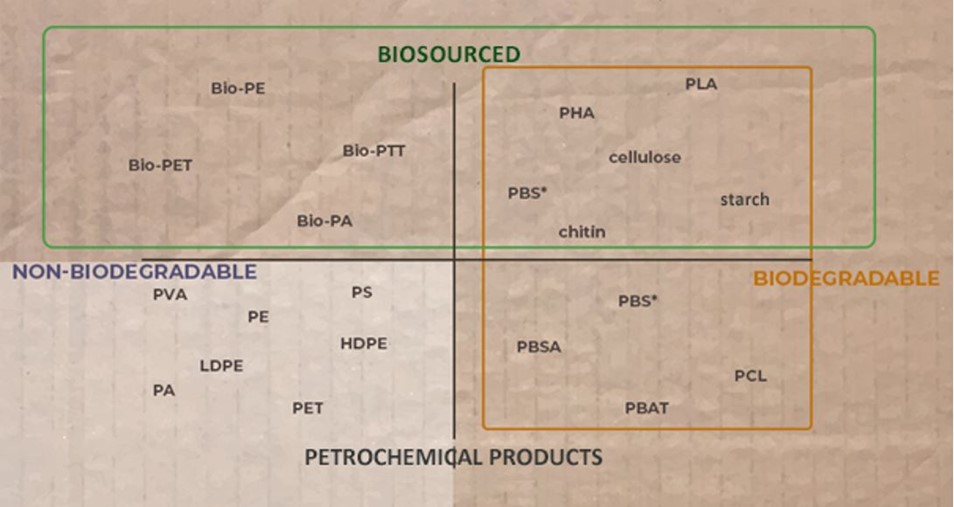

"There are many concepts concerning sustainable packaging… And it is easy to get lost," comments Thomas Karbowiak, lecturer in physico-chemistry at AgroSup Dijon. For the researcher, there is a simple way to visualize the differences between each of these concepts: "I represent the existing materials according to a 2-axis diagram: one going from "petrochemical" to "biobased", the other going from "non-degradable" to "biodegradable". This avoids an over–simplistic vision with shortcuts.”

* PBS monomers may be obtained from petrochemical or renewable resources

Dark background: bioplastics (vs. light background: non-bioplastics).

Thus, at the bottom left of this diagram, we find conventional plastics, some of which can be recycled and reused for the same purpose. This diagram also reminds us that there are materials derived from petroleum which are biodegradable (PCL, PBAT, PBSA), while some biobased materials are also not biodegradable (bio-PET, bio-PTT, bio-PA). "Biobased and biodegradable are two different concepts", explains Thomas.

Indeed, if the term "bio-based" refers to the raw materials used which must be derived from biomass (such as rice, potatoes, soybeans, sugar cane, corn, mushrooms, etc.), the term "biodegradable" refers to the decomposition capacity of a material under the action of micro-organisms (bacteria, fungi, worms...).

"Bioplastics": the importance of the plural

According to the European Bioplastics 2019 report, bioplastics represent 1% of the world's annual plastic production. But what are they? First of all, it is important to note the plural, “bioplastics”, because there are actually several different types, since the prefix "bio" may refer to "bio-based" or to "biodegradable".

Bioplastic therefore refers to materials derived either from bio-based plastic materials (for example, corn or sugar cane), or, if they are biodegradable, from fossil resources (petrochemical reactions)… "or both!" , adds Thomas Karbowiak. Some plastics, such as PHA (polyhydroxy alkanoates), polyesters produced by bacterial fermentation of sugars or lipids (often a waste recovery), or PLA (polylactic acid), which can be obtained from starch from corn, sugar beet or sugar cane, are both bio-based and biodegradable.

"With renewable materials, such as corn, we can also obtain materials similar to those derived from petroleum: for example, we can produce polyethylene. It will then be called bio-PET (for ethylene bio-terephthalate) since the resource used is renewable – unlike petroleum. However, it will not be biodegradable."

While PHA and PLA are frequently used in food packaging (egg cartons, fruit and vegetable packaging, food trays, etc.), there are more and more innovations in bio-based packaging. For example:

- In Australia, the company Alpla has developed coffee capsules made from bio-based organic materials, in particular from sunflower husks. Biodegradable at home within 6 months, these capsules are also available with a home composter bin to encourage consumers to adopt these practices.

- Nestlé has developed bio-based paper packaging for its cereal and fruit bars, suitable for high-speed bagging machine lines (designed to handle plastic) and ensuring the quality and freshness of the product.

- The company Rapuk has developed a 100% bio-based packaging for sandwiches. The cardboard is made from stalks and leaves of rice, wheat, corn, and sugar cane. This is a smart way to exploit these harvest by-products, most of the time burnt (only 20% of these by-products are currently used). Recyclable up to 7 times, this packaging is fully home-compostable.

Biodegradable vs. compostable: different certifications

The biodegradable and the compostable are positioned as sustainable alternatives… And even if the concepts seem widely understood, there are regulatory frameworks to obtain the corresponding certifications. "There are precise regulatory frameworks for biodegradability and compostability," specifies Thomas Karbowiak, "taking into account both the degree of decomposition of a substance and the time required to obtain this decomposition."

"First of all, regarding biodegradability, two conditions are possible," he explains, "either aerobic (that is to say, in ambient air) or anaerobic (that is to say, in the absence of oxygen)." Thus, in aerobic conditions, the packaging material must be at least 90% degraded in 6 months to be considered as biodegradable. Under anaerobic conditions, its biodegradability capacity will be evaluated according to a biogas production of 50% in 2 months. If a packaging meets these conditions, a certificate and associated logo may be obtained: the "OK biodegradable" logo, managed by TÜV AUSTRIA Belgium, which also specifies the environment of the biodegradability (soils, fresh water, or marine environment).

Thomas Karbowiak continues: "If we go even further, a material may also be compostable under conditions again defined by regulations. What is fundamental in this regulation is the rate of degradation, which must be compatible with other known compostable materials and without leaving visible, distinct or toxic residues.” Thus, under aerobic conditions, after 84 days, no more than 10% of the initial dry mass of the material should remain after passing through a 2mm sieve.

"There are several logos to promote a compostability certification," specifies Thomas Karbowiak, "which in particular make it possible to distinguish industrial composting from home composting." For example, the "OK Compost Industrial" logo certifies a composting carried out at 58°C in less than 6 months, under aerobic or anaerobic conditions: this is the case for PLA, for example. At the same time, the "OK Compost Home" logo certifies composting that can be carried out at room temperature – 28°C – in less than 2 years.

Further information

The purpose of a food packaging is, first of all, to preserve food, taking into account its shelf life and the stability of the packaging. But limiting food waste and the production of waste has also become essential and makes packaging, to this day, a complex and wide-ranging subject, in perpetual search for innovations... Hence the multiplicity of concepts, that are sometimes difficult to grasp! To learn more about innovation in sustainable packaging, read our special issue of the Focus on Food Trends here or access our webinar on the subject here (replay available in French).

At Vitagora, we are engaged in several innovation projects related to sustainable packaging: for example, the European Glopack project, in which Vitagora is a stakeholder, aims to develop and market sustainable, bio-based, biodegradable, and active food packaging solutions (find out more here).

To learn more, subscribe to our blog so you don't miss any posts (around 2 to 3 emails per month)!

Home

Home

Share your opinion